(11/27/2022)

I mentioned earlier that the vehicle has sat a long time. Unfortunately what happens with a lot of vehicles that sit – they get moldy.

This was one of the more challenging parts of the car for me. I needed to clean the interior to remove any traces of mold/mildew, but I needed to do it safely (mold is dangerous for anyone and I’m especially sensitive to it) and do it in a way that didn’t trash the interior.

The first thing I tried was a “mold bomb” – this is one of those aerosol cans that fogs an area. Complete bust. Complete waste of money. This thing did something and sputtered and then just made a mess. 0 out of 10 would recommend.

After a lot more reading online, I came up with this solution. This is a disinfectant / cleaner and then there is another product from the same company that is a mildew cleaner. The combination of these two items seem to do the trick on all of the interior. Everything I’ve used it on has been left clean and smelling nice and does not seem to affect the materials.

This is after the first spray down of the dash and steering wheel. A little hard to see in the picture, but you can see on the right side where I stopped and the mold is still there.

This door card wiped up so nice! All of the leather is then sprayed down with a leather cleaner/treatment from The Chemical Guys.

The interior plan is as follows:

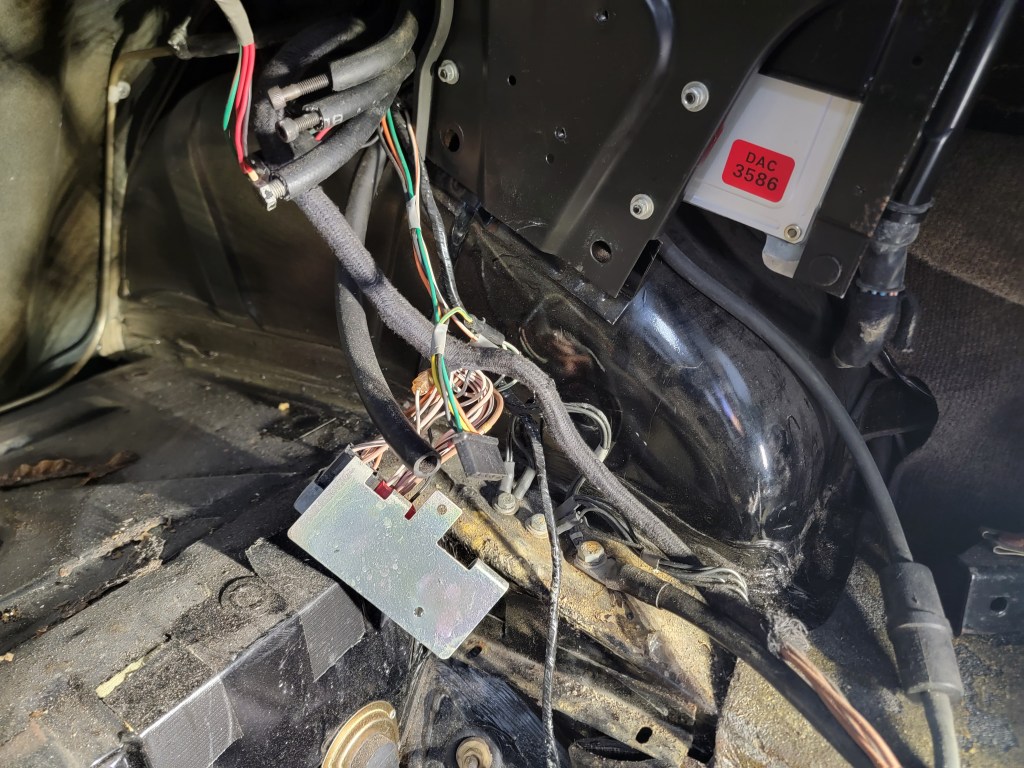

- Clean everything inside the car

- Remove everything from the car

- Disassemble as much subsections as I can (like the door card can come apart in like 4 pieces)