(12/29/2025)

I needed a way to easily get the motor on and off of my floor jack, or in and out of the cradle. Because of limited space and a sloping driveway, a traditional engine hoist/cherry picker wouldn’t work well.

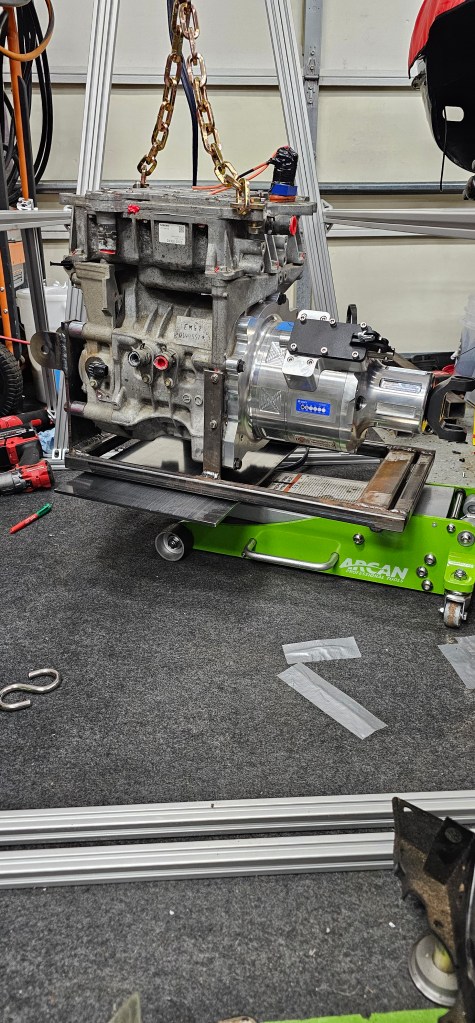

So….I made this thing:

I was happy to see the motor, TorqueBox and cradle all weigh only 222.2lbs – – maybe that’s a lucky number now?

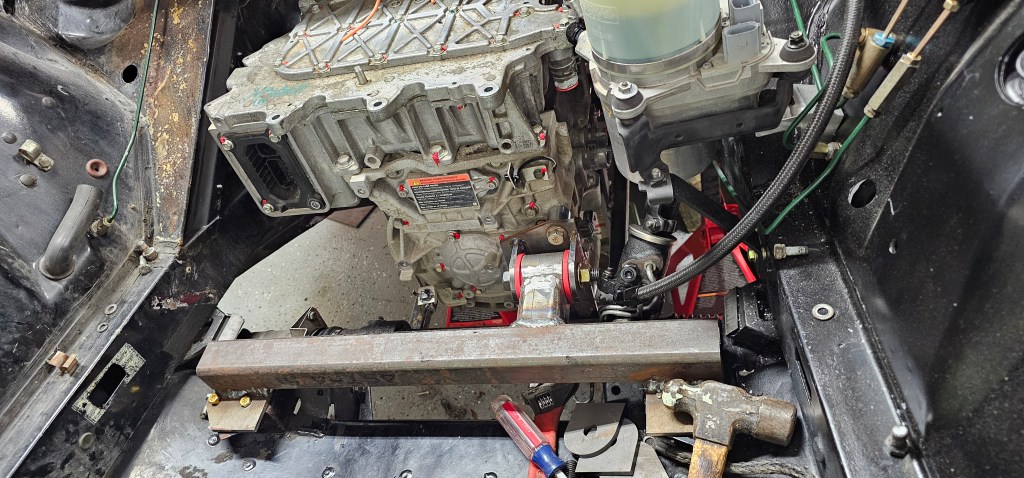

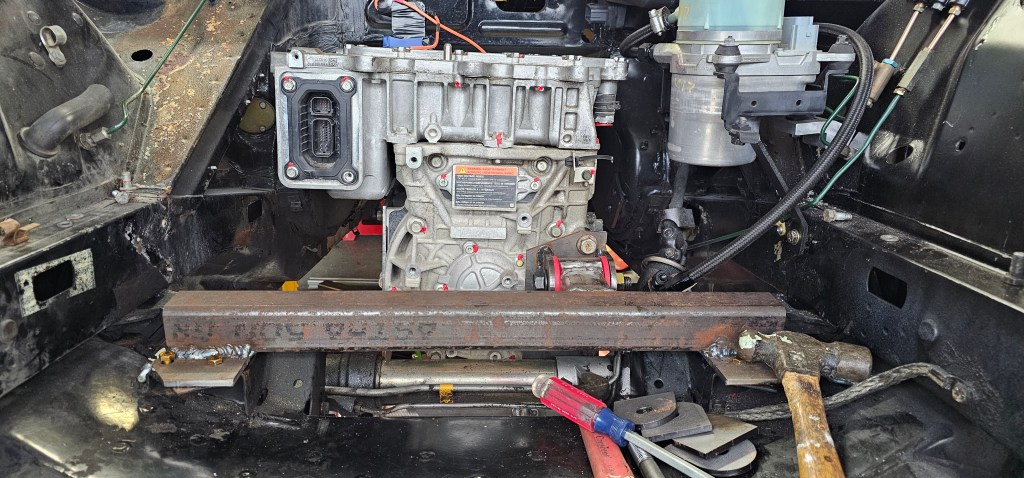

Once I had the motor assembly on the floor jack, I lifted it back into position and connected the front motor mount for the first official time.

Now the next step is to make spacers for the plate that goes where the transmission was (to clear the driveshaft) and fabricate the trailing arms. The PVC driveshaft placeholder fits exactly as it should.